Professional stamping parts manufacturers are extremely important in the medical industry. Metal stamping is a vital manufacturing process for new energy cars, notably electric ones, that helps create complicated components that meet tight automotive criteria and norms. At the same time, metal stamping contributes to the large volume manufacturing of components for medical equipment.

Metal stamping technology is critical for these sectors’ growth since accuracy, quality, and size are significant criteria for components in these industries.

Consider The Following Metal Stamping Uses In The Medical Industry:

Gastrointestinal Equipment

Metal-stamped medical gadgets are assisting in the medical industry’s increasing expansion. Many GI or gastrointestinal gadgets components may be made with accuracy utilizing medical stamping. Gastrointestinal stents, for example, are rather prevalent. Furthermore, various surgical equipment is produced in this way.

Dosing Equipment

Devices for measuring and administering liquid drugs are also essential components of any healthcare system. For example, metal stamping can assist in producing these dosage devices with accurate dimensions and specifications, allowing doses to be delivered with total precision.

Microscopes for Measuring

Measuring microscopes are a kind of optical microscope that can precisely measure targets. For example, measuring microscopes need multiple metal pieces, and metal stamping may assist in precision manufacturing.

Why Is Metal Stamping So Important In These Industries?

Metal stamping is critical for creating highly specific components at a low cost, which is in great demand in these sectors. Here are some important reasons why metal stamping is so important in the NEV and medical sectors.

Cost-Effectiveness: Metal stamping may be quite cost-effective. This is because the manufacturing line may be changed as required. For example, you may include as much automation, physical labor, and equipment as possible. Choosing the correct equipment and methods might help you save money in the long run.

Material Efficiency: Metal stamping is often accomplished utilizing specialized equipment and technology that may assist in the efficient creation of high-volume or low-volume goods as required. Many identical, high-quality components may be produced at breakneck speed.

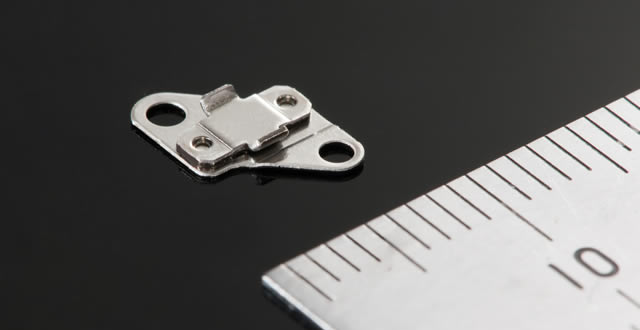

High Precision Accuracy: One of the main reasons people favor metal stamping is its precision and accuracy. This is because metal stamping processes depend on automated equipment and technology to provide precise and accurate outcomes. Metal stamping is the greatest option for businesses that need exceptionally accurate outcomes, such as the medical and new energy vehicle industries.

Manufacturer Of Professional Metal Stamping

Consider dealing with Hashimoto if you need a dependable metal stamping company. This is why!

In its metal stamping procedures, Hashimoto utilizes cutting-edge technology. Over 40 punching and optical grinding equipment are available on our manufacturing line, allowing us to handle all sorts of products properly and effectively.

Hashimoto Precision is a one-stop shop for all of your metal stamping requirements. We will not only design the die but also manage the mass production of your components before they are ready for assembly.

Finally, Hashimoto has the knowledge and expertise to handle a wide range of metal stamping applications. Since our inception in December 2002, we have established ourselves as the go-to source for metal stampings.

TRUTHREVIEWERS

TRUTHREVIEWERS